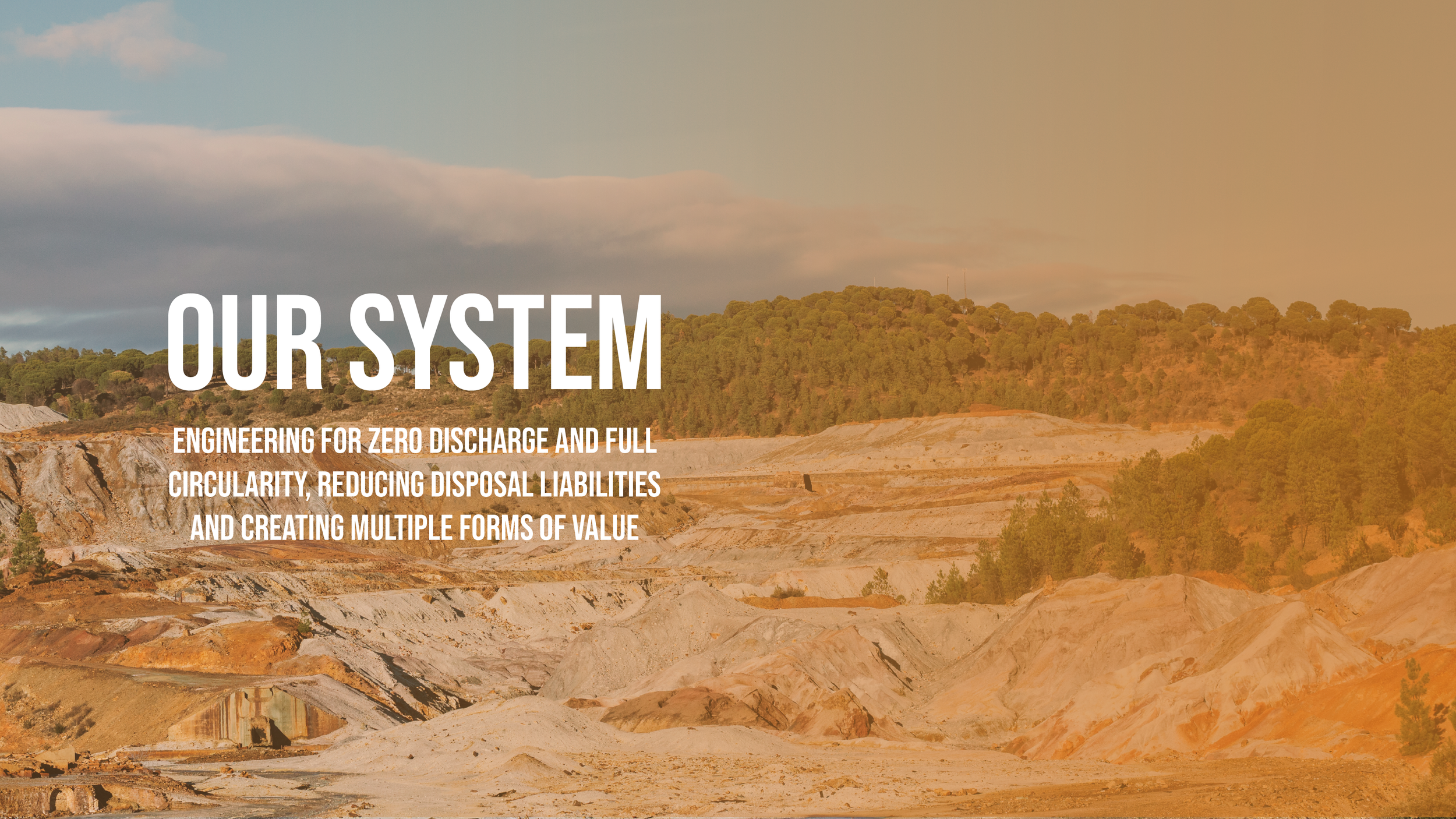

INNOVATIVE METAL & RECOVERY SOLUTIONS

We provide a circular solution that recovers metals and turns all leftover materials into renewable energy and carbon-based products.

WE INTAGRATE METAL EXTRACTION AND RENEWABLE WASTE ENERGY

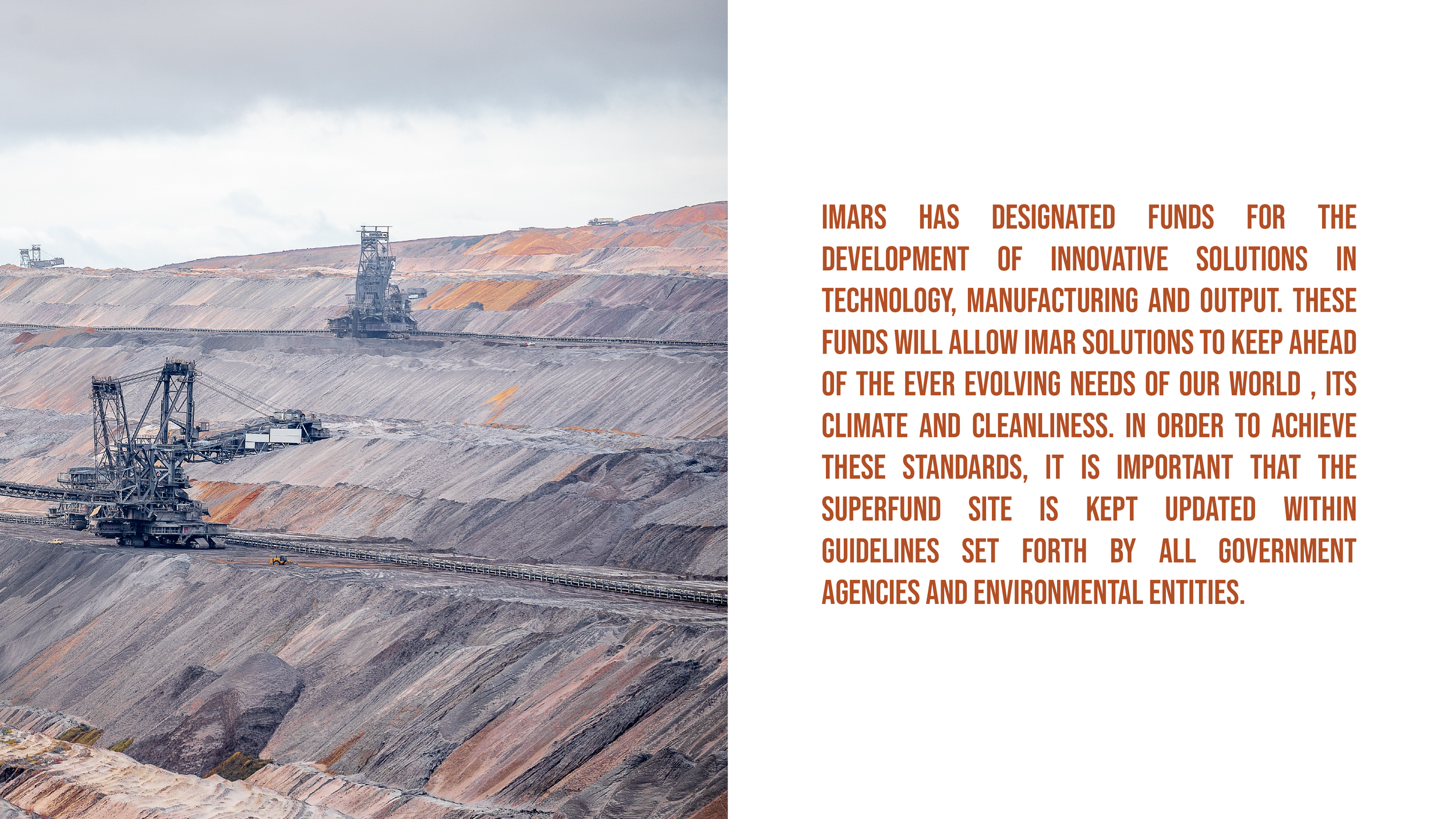

IMARS delivers a modular, scalable, and regulatory-compliant circular solution designed for superfund sites, industrial facilities, mining operations, steel and smelting plants, municipalities, and waste to energy hubs.

Our two-phase system delivers advanced technologies for recovering valuable materials and converting all residuals into renewable energy and carbon products.

FROM WASTE TO CLEAN ENERGY

IMARS’ Zero-Discharge Renewable Waste-Energy process transforms all non-metal residues into meaningful sources of value. Using our proprietary, patent-owned technology, fines, dust, and mineral residues from metal recovery are blended with approved waste streams to create a high-BTU feedstock for controlled thermal conversion. This advanced system produces renewable outputs such as syngas, liquid fuels, electricity, activated carbon, char, and reusable moisture—eliminating the need for disposal and delivering true zero-waste performance.

Engineered to operate with minimal emissions and full regulatory compliance, this second-stage platform supports carbon-offset generation and strengthens ESG outcomes for industrial, mining, and regulated sites. Through this process, IMARS ensures that every remaining material is upgraded into energy, carbon products, or reusable resources, driving circularity and long-term environmental value.

-

Waste Feedstock Blending and Optimization Fines and waste streams from metal extraction are combined with approved organic and synthetic wastes, plastics and biomass. By engineering the blend, IMARS optimizes calorific value, moisture content and consistency. This provides a stable feedstock that maximizes syngas yield and fuel production while maintaining steady-state operations.

-

Pre-Processing Through Shredding and Drying The Renewable Waste-Energy system shreds and homogenizes mixed feedstock to a consistent particle size and employs advanced drying technology to reduce moisture content to approximately three percent. Effective pre-processing increases thermal efficiency, reduces parasitic energy loads and provides precise control over conversion conditions.

-

Thermal Conversion into Energy and Carbon Commodities Under controlled, oxygen-limited thermal conditions the prepared feedstock is converted into several primary product streams. Syngas, typically representing forty to fifty percent of output by weight, is a hydrogen-rich gas that can fuel industrial heat systems or combined heat and power units or be upgraded into synthetic fuels. Pyrolytic liquid fuel, often yielding twenty-five to thirty-five percent of output, functions as a renewable heavy-oil substitute. A solid carbon-rich fraction of roughly ten to twenty-five percent becomes tech-grade char suitable for activated carbon, filtration media, soil enhancement or construction composites. These product ranges depend on the specific feedstock blend and operating parameters.

-

Energy Recovery and Power Generation Syngas produced by the system can be routed to turbines, engines or boilers for on-site power generation and thermal use. At commercial scale, the design supports generation on the order of megawatts per ton of processed material, enabling industrial sites or energy parks to offset grid demand, operate microgrids or export power under appropriate interconnection agreements.

-

Environmental Credits, Moisture Reuse and Circular Outputs Each ton of waste diverted from landfill and processed through the Renewable Waste-Energy system can support verified reductions in greenhouse gas emissions and contribute to carbon credit or ESG reporting programs. Moisture extracted in pre-processing is captured and conditioned for potential use in irrigation, dust control or construction processes. Remaining mineral solids are further refined for use as additives in aggregates or composites. In this way, Process 2 is designed to operate as a zero-discharge, fully circular waste-to-value solution.

-

– Hydrogen-rich syngas for heat and power

– Liquid fuels as heavy-oil substitutes

– Tech-grade char and activated carbon products

– Electricity and microgrid opportunities

– Reusable moisture and mineral residues for industrial applications

-

● Syngas (40%–50% yield)

A clean, hydrogen-rich gas used in industrial power systems, combined heat and power (CHP) applications, or upgraded into synthetic fuels like methanol and hydrogen.

● Pyro-Oil (25%–35% yield)

A dense liquid fuel derived from thermal decomposition of plastics and biomass. Acts as a renewable diesel substitute or can be used for heavy-oil displacement in industrial burners and marine engines.

● Tech-Grade Char (10%–25% yield)

A solid carbon-rich byproduct used for soil remediation, activated filtration systems, carbon sequestration, and as an additive in sustainable concrete and construction composites.

● Carbon Offsets

Each ton of organic or synthetic waste diverted from landfill and processed through the Smart Waste System can generate verified CO₂ emission reduction credits, contributing to ESG and decarbonization targets.

● Energy Generation

The integrated Smart Waste technology design enables on-site energy recovery from syngas, with the potential to generate up to ~1.2 megawatts of electricity per ton of processed waste material, supporting off-grid operations, microgrids, or facility energy independence.

Advancing Sustainability and Recovery | Engineering Circular Solutions

-

The ownership and senior management team brings a combined century of experience in the following business sectors

Finance, International Banking, Private Equity and Funding.

Production implementation and management of manufacturing facilities within the metal and fabrication industries.

Distribution and Logistics Warehousing.

High Level Inside and Outside Sales & Marketing.

Technology Invention and Creation of Proprietary Equipment and Technology to manage the refining process and beyond.

Business and Office Management.

HR, Legal, Bookkeeping, Purchasing and Inventory Management.

IT and cyber security.

-

● Waste Remediation: Elimination of hazardous slag from the Chemetco Superfund site.

● GHG Reduction: Significant decrease in greenhouse gas emissions through waste diversion.

● Real-World data gathering: improving predictive models (A.I.) and accelerating smarter, more efficient waste and circular economy services.

● Job Creation: Employment and education opportunities in operations, logistics, and maintenance.

● Community Revitalization: Economic development.

● Infrastructure: Providing an end-to-end plan in place for compliance, regulatory and safety.

-

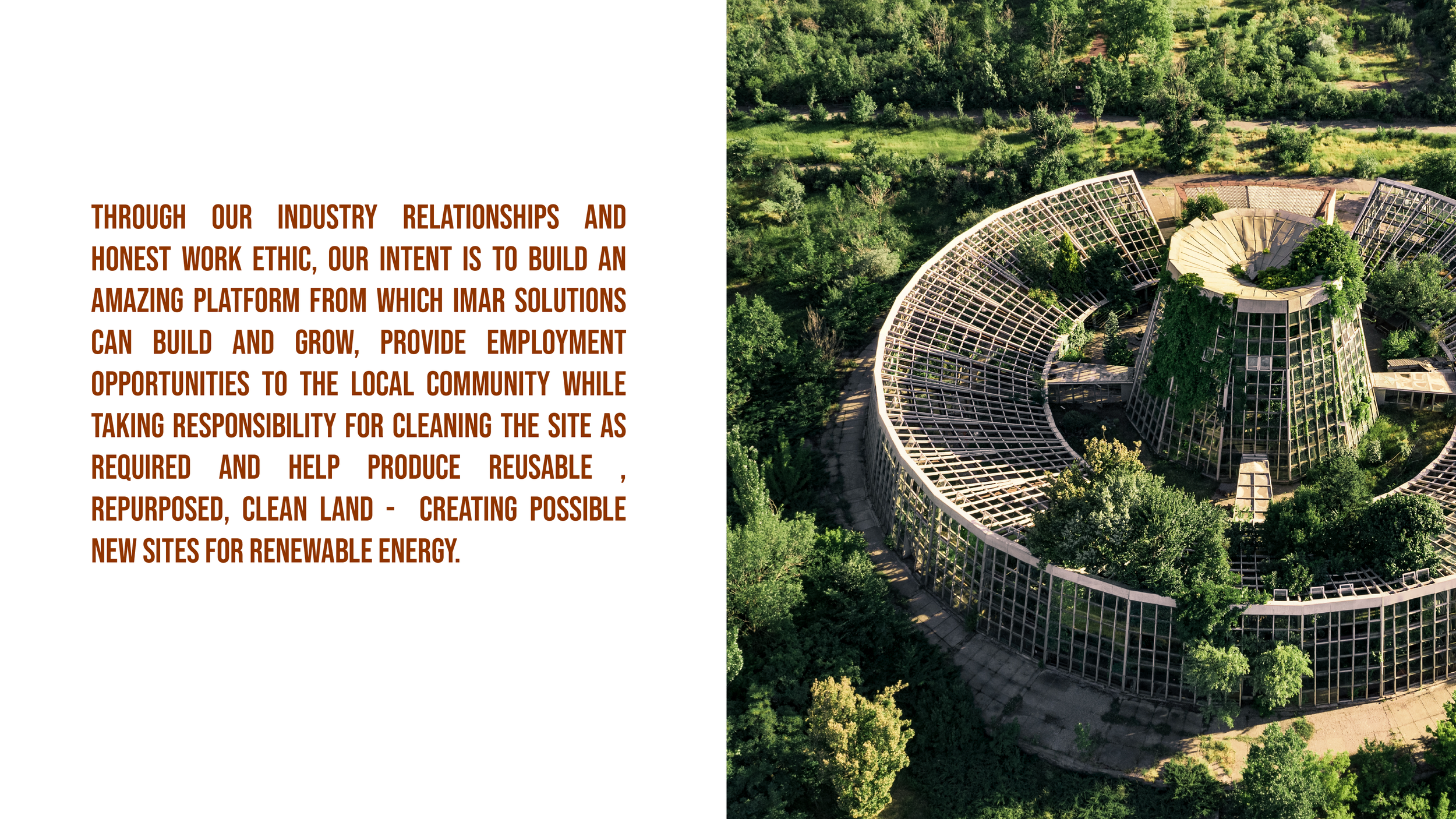

●Environmental: Legacy waste elimination, renewable energy production.

●Social: Community engagement, job creation, public health improvement.

●Governance: Transparent JV structure with IMAR, compliance with environmentalregulations.

-

–Maximized metal and energy recovery from complex waste streams.

–Zero-discharge, zero-landfill design with minimal emissions.

–Regulatory-compliant operations suitable for Superfund and other sensitive sites.

–Multiple revenue streams from metals, energy, carbon products and environmental credits.

–Scalable, modular deployment across industrial, mining and municipal locations.